That's interesting, as I was thinking that the evolution of long recharging times would have been replacing the entire battery in a swift move instead of plugging and wait for the recharge to complete. The batteries could then be recharged offline. That would require a standard form factor(s) for batteries.

That seemed to be the thought a few years ago but quickly became an impossibility. For packaging, different manufacturers, etc battery packs won't be easily swapped. Plus for now it's not a huge issue as most trips are short so you're starting off with a full charge. In a Tesla the supercharging stations don't take *that* long to charge. And if you're really doing trips that would require multiple charges, you probably have a gas car anyway for now.

My $18K Hyundai didn't have panel gaps, so I don't see how it is okay for anything other than a Yugo. I tolerate it on the Model 3, but hope they get that figured out. Tesla seems to sort out a lot of things as they go forward and don't update bodies as often as other cars.

I think Tesla sunroofs were stopped 5 years ago. I was never a fan of sunroofs or T tops on any cars, with T tops being the worst.

The lack of changes is something I was reading about recently being an issue for Tesla. People LOVE new models. If you look at sales of most cars they're high at the beginning of a model and then drop off until they come out with a refresh or new model.

Tesla seems to make mini-changes as they go along, some of it really hard to figure out if you're not a Tesla nerd. It works for Tesla as they have a ton of control over their cars and don't have a lot of 3rd party parts.

The panel gaps is really just a great point at how Tesla is new to the car game. Old car manufacturers were figuring out a ton of things decades ago when people were still making clay molds and drawing by hand. Tesla had to start fresh but do seem to be making a lot of improvements quickly. And without relying on outsourcing like some companies.

yes thats my point, i was taking his own argument to an extreme to make it.

mechanical parts probably (the engine/transmission do make up the bulk of parts on a traiditional vehicle) but evs have more computers and software to have issues with. But the engine/transmission problems are pretty rare on modern cars anyway(especially below 100k miles)

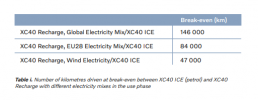

did you read the paper from volvo posted earlier in this thread? in order for an ev to generate the same amount of carbon emissions than a comparable ice powered vehicle it needs to be owned/driven something like 92k miles and it doesnt account for battery replacement in that window (im not sure if it includes the disposal portion of the lifecycle either) How many people do you know that keep a car that long (im sure many of us in this thread keep ya longer than that, but that is definitely NOT the norm.

also what actually happens to the old batteries? i cant find any companies that actually disassemble them and resuse the materials, im guessing they all get shipped to a landfill in china . . . .

Please tell me how an EV has more computers than an ICE engine that needs a computer that properly runs an engine including the spark and the timing of it to the cycle along with the valve timed to the cycle, speed and load and regulating emissions. Plus taking into multiple sensors and dealing with those sensors that wouldn't exist on an electric car.

-Coolant sensor (Can exist on many EVs, probably anything but a Nissan)

-Crank/camshaft positioning sensor

-O2 Sensor fore and aft of the cat.

-Engine Temp Sensor

-Oil level sensor

-MAF sensor

-Oil pressure sensor

-Intake Air temp

-Knock sensor (Typically on turbo cars which is everything now it seems)

-Throttle position sensor

-MAP sensor

-Fuel pressure sensor

-Coolant LEVEL sensor (wouldn't be surprised if liquid cooled batteries had this)

Wheel speed on an EV uses the same ring as ABS which every car now has. Outside of the electronics for the inverter, what does an EV really need?