Hey, I'm reading! Post details! Our better yet a whole build thread

Word, I like cars! I just don't own any fun ones.

I like Defenders

Sorry it's been a long time since I was on last. Holidays then was up in VT.

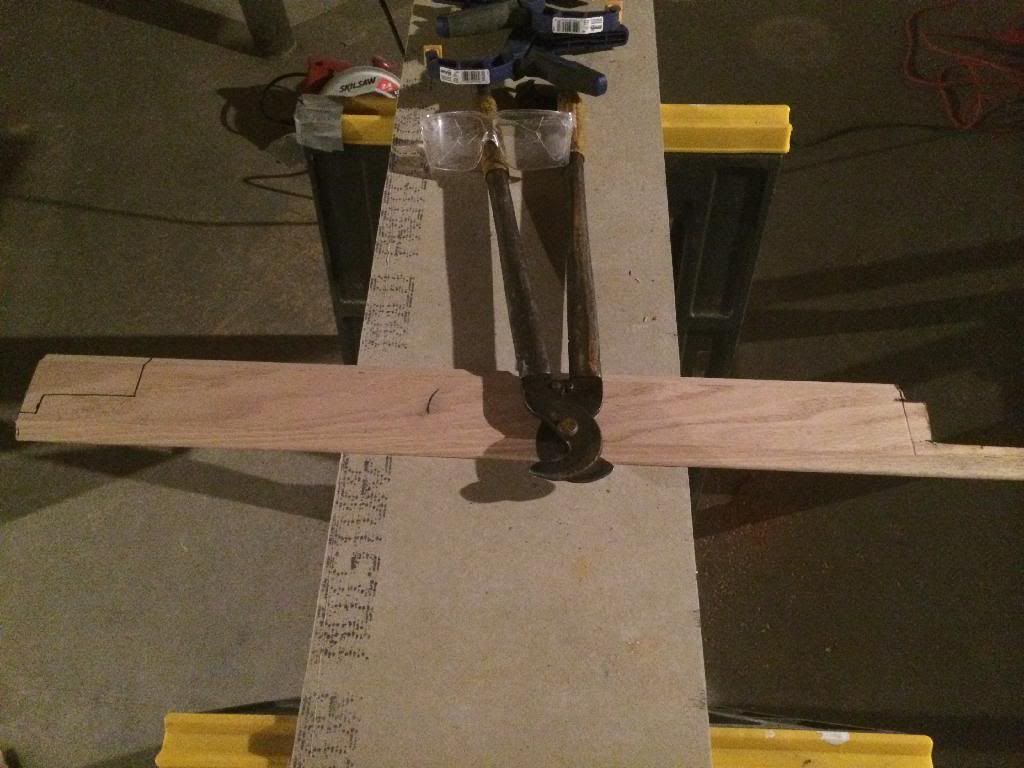

Specs on the pics:

- LR Defender 110 Galvanized frame made by Marshland

- LR Discovery 1 axle housing, modified to fit a Toyota E-Locker 3rd member, 4.11 gearing

- LR OEM HD springs

- RoverTracks HD trailing arms

- RoverTracks HD axle shafts (stock LR is 24spline these are 30 spline)

- EBC slotted/dimpled rotors (I know flat/stock is probably better) and EBC greens

- New ball joint and bushings in the upper arms, they were also painted with Eastwood Chassis Black Extreme.

- Axle was painted using POR-15 then top coated with their Chassis Black

- RTE Fab shock mounts -- upper and lower. Bought used and repainted using Eastwood CBE.

- ordering Fox Emulsion 2.0 for the shocks soon.

- LR Discovery Steel rims with Goodyear MTR/Kevlar 315/75/16 (35" tires).

Overall build: rebuild an '86 that I had imported this past summer. Frame is ratty so I'm just going to do it correctly. I had those HD axles on my NAS 90 and pulled them off before I sold it. It's powered by a 2.5 NA diesel but I am looking to update to a Merc OM617 300TD. My plan is to refurb the running gear but keep the body as is with the dents and scratches and shitty paint. Interior will be done over as well.

Add on:

I am hoping my end result will be something like this:

http://www.copleymotorcars.com/?showroom=1994-land-rover-defender-110-convertible-2

Softtop and caged like the one above but way more off-road capable and forward facing seating (using 3 point belts)

![IMG_0796[1].JPG](/forum/data/attachments/12/12263-6484b77f49fb142671274995747b950a.jpg)

![IMG_0797[1].JPG](/forum/data/attachments/12/12264-26a8087351230a8004a94ccb6e5d1c1c.jpg)

![IMG_0798[1].JPG](/forum/data/attachments/12/12265-480f154803f8225e2249a9d02025f476.jpg)